Sustainability

Itoki SDGs Declaration

Based on our vision statement of "For lively people, and a green Earth," the Itoki Group has established initiatives to support the working activities of all people. Having set our sights on the vital goals for the international community as outlined in the development goals that are sustainable up until the year 2030 (SDGs) established by the United Nations in 2015, we have been contributing to achieving individual happiness, corporate happiness and social happiness by establishing initiatives for both attaining the economic value of the company and solving social issues.

Materiality

Itoki has established materiality (vital issues) based on an analysis of the risks and opportunities posed by the business environment in order to solve diverse issues surrounding the workplaces and strive to "Make society and people happy" and "Make the company and its employees happy". We will drive our business activities based on this materiality to solve social issues, thereby leading to sustainable social and corporate growth.

*Click the image to enlarge

Signing the United Nations Global Compact Pact

Itoki signed the United Nations Global Compact pact in June 2018. The United Nations Global Compact pact is designed to encourage all companies and organizations to take part in worldwide initiatives for autonomously achieving sustainable growth by demonstrating responsible and creative leadership and acting as responsible members of society. Participants are required to support the ten universal principles pertaining to human rights, labor, the environment and anti-corruption advocated by the United Nations, and to contribute to creating a sustainable society.

We are also taking part in activities established by a sub-committee sponsored by the local network in Japan, the Global Compact Network Japan, in order to solve issues related to SDGs.

For further details, visit the Global Compact Network Japan website.

Approval of TCFD Recommendations Announced

In June 2020, the Itoki Group announced our support for the TCFD (Task Force on Climate-related Financial Disclosures) recommendations in recognition of the importance of addressing climate change as a management issue. We will analyze the impact of climate change on our business based on the TCFD recommendations.

Itoki Group ESG Policy

Itoki Group has formulated its ESG policy with the aim of realizing "Vibrant People, Beautiful Planet" in society.

Itoki Group, as a company that creates people's "Working Environment," shall strive to solve problems to achieve a sustainable society while addressing environmental issues.

Environment

Itoki Group shall continue to practice environmental conservation activities in its business activities, including the manufacture of products and provision of services, in order to create a " Lively Earth " society.

Social

Itoki Group, including its supply chain, shall strive to improve the working environment, including respect for human rights and the elimination of harassment, in order to create a society in which "people can also be vibrant". We shall also make efforts to enable our diverse human resources to perform at their fullest potential.

Governance

Itoki Group shall commit to transparent and reliable management for sustainable business growth, comply with relevant laws and regulations and compliance, and ensure thorough information security. In addition, we shall emphasize dialogue with stakeholders to ensure the continuation of sound business operations based on diverse external perspectives.

ESG Action Plan

Environment

Climate change

Itoki Group shall promote adaptation to climate change and proposed countermeasures by analyzing the business risks and opportunities caused by climate change and clarifying the details of its initiatives.

Resource recycling

Itoki Group will actively promote the effective use of limited resources in all areas of its business activities as an initiative leading to decarbonization.

Biodiversity

The Itoki Group shall engage in sustainable procurement from the development stage of its products and services in order to keep the planet lively.

Social

Human rights

Itoki Group shall, in order to allow all people to be lively and active, in all of its business activities and all of its relationships in the supply chain, make efforts to respect human rights.

Labor practices and health management

Itoki Group shall promote fair and healthy industrial relations and maintain an environment that utilizes the individuality of multifaceted human resources and providing total support both within and outside the company for processes aimed at realization of health.

Diversity and inclusion

Itoki Group shall create a workplace that has an organization, environment and culture in which all workers can show respect for each other's backgrounds.

Governance

Engagement with stakeholders

Itoki Group shall, by means of dialog with stakeholders within and outside the company and active participation in various development, deepen understanding of Itoki Group, heighten the feeling of expectation for growth, and work for the increase in value for both parties.

Corporate governance

Itoki Group shall promote CSR management integrated with our business strategy and aim for sustainable growth of both society and our business operations. We shall recognize CSR as an important management problem for the creation of company values and make efforts accordingly.

Fair dealings and prevention of corruption

Itoki Group shall, as well as of course adhering to laws and ordinances, establish a system promoting ethical compliance, which shall form the basis on which to build a fair and transparent relationship with our stakeholders in which corruption is not tolerated, and make efforts to strengthen and ingrain a consciousness of ethical compliance throughout the entire Group.

Information security

Itoki Group recognizes that appropriate handling of information related to management is a social responsibility of Itoki Group, and shall endeavor to earn the trust of society through continuous strengthening of information security management systems, including privacy protection.

Disclosure of information

Itoki Group shall make efforts to disclose information in an appropriate and timely manner, not merely abiding by the relevant laws and ordinances and timely disclosure rules but to deepen understanding of Itoki Group on the part of all of our stakeholders.

Other Policies

Environmental Policy

Human Rights Policy

Health and Safety Policy

Environment

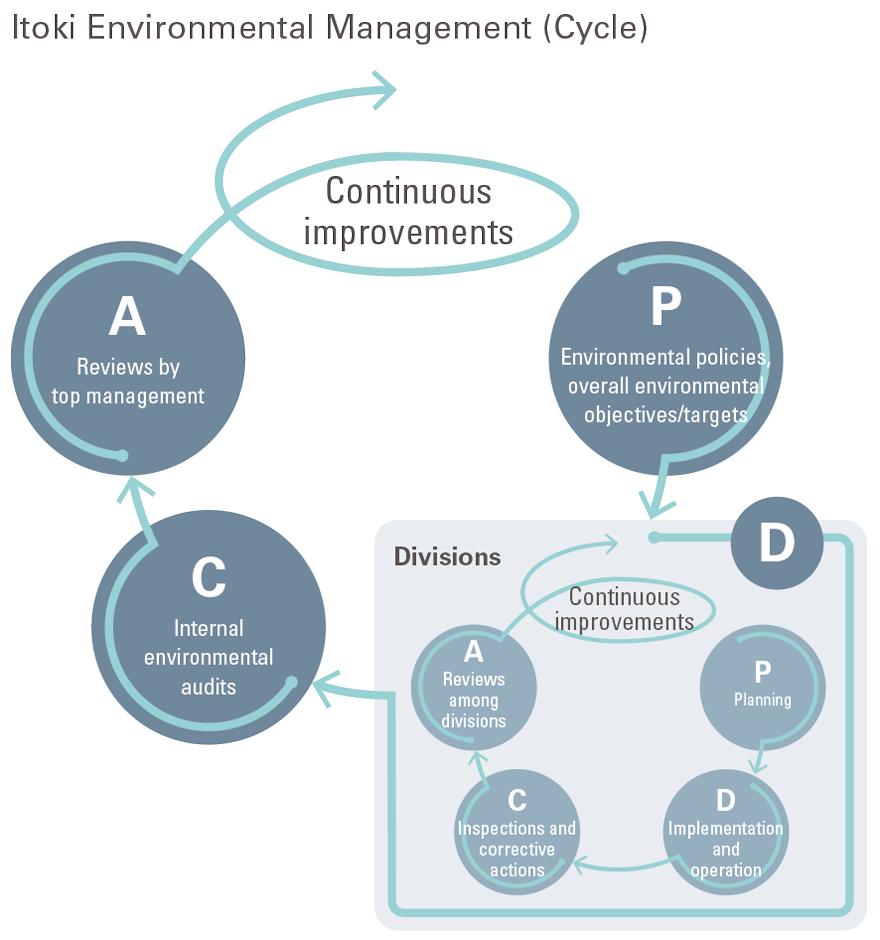

Environmental Management

The Itoki Group operates an Environmental Management System based on our Itoki Environmental Policies, which regulate our environmental activities, and on our detailed Action Policies, and we strive to ensure that improvements are constantly being made.

Long-Term Environmental Plan

The Itoki Group has announced a target to reduce CO2 emissions by around 30% over 2013 figures by the year 2030 based on the Itoki Group Environmental Policies, and we enact Mid-Term Environmental Plans that represent detailed action plans once every three years.

Promoting the most efficient use of limited resources, biodiversity conservation and global environment burden reductions enables us to contribute to creating a sustainable society.

Environmental Management System

Ever since we first received certification in November 1999, Itoki has been implementing constant improvements to promote environmental conservation activities and strictly observe environmental compliance covering all aspects of our business, from manufacturing through to sales, in accordance with our ISO14001-based Environmental Management system. We have also expanded certification to cover the entire Group to involve all Itoki Group elements in environmental activities on an independent basis. The results of these activities are shared with top management, and the projects and their results publicized within and outside of the company.

*Click the image to enlarge

Effective Use of Resources Throughout the Life Cycles of Products

The Itoki Group is working to ensure that resources are used effectively throughout the life cycles of all products (design, procurement, production, transportation, usage, disposal). We have established targets for reducing waste, increasing the amount of waste recycled and reducing the amount of water used, and are striving to ensure the observance of the 3Rs for all resources, including the materials, water, packaging and other secondary resources used during production.

*Click the image to enlarge

Society

Promotion of sustainable Procurement

Instead of just taking our social responsibility into account within the company and throughout the group, we have recently begun demanding the same from our suppliers.

The Itoki Group has issued a sustainable Procurement Guidebook to promote sustainable procurement activities that take compliance, the environment, human rights and other issues into consideration within both the Group and our suppliers. We have distributed sustainable procurement check sheets to all suppliers who meet certain standards so that we can check on the progress each company is achieving. We intend to continue establishing mutual links with suppliers into the future as part of our procurement activities that take social responsibility into account.

Sustainable Procurement Guidebook(English Edition) *Ex-CSR Procurement Guidebook

Diversity & Inclusion

Based on our top commitment, Itoki has set targets to make the best possible use of the "lively" characteristics of and bring out the best performance in each and every one of our diverse range of human resources, who share a wide range of genders, ages, nationalities, disabilities, employment styles, working methods, customs and sense of values, etc.

Promotion of Global Human Resource Activities

A large number of employees with foreign nationality are currently working for Itoki. As each of these have different backgrounds, our local employees are studying English and Portuguese and actively engaging their work colleagues in conversation to promote communications. Greeting people in their native tongues and casually engaging them in conversation helps nurture a corporate culture that is open to accepting diversity within the workforce.

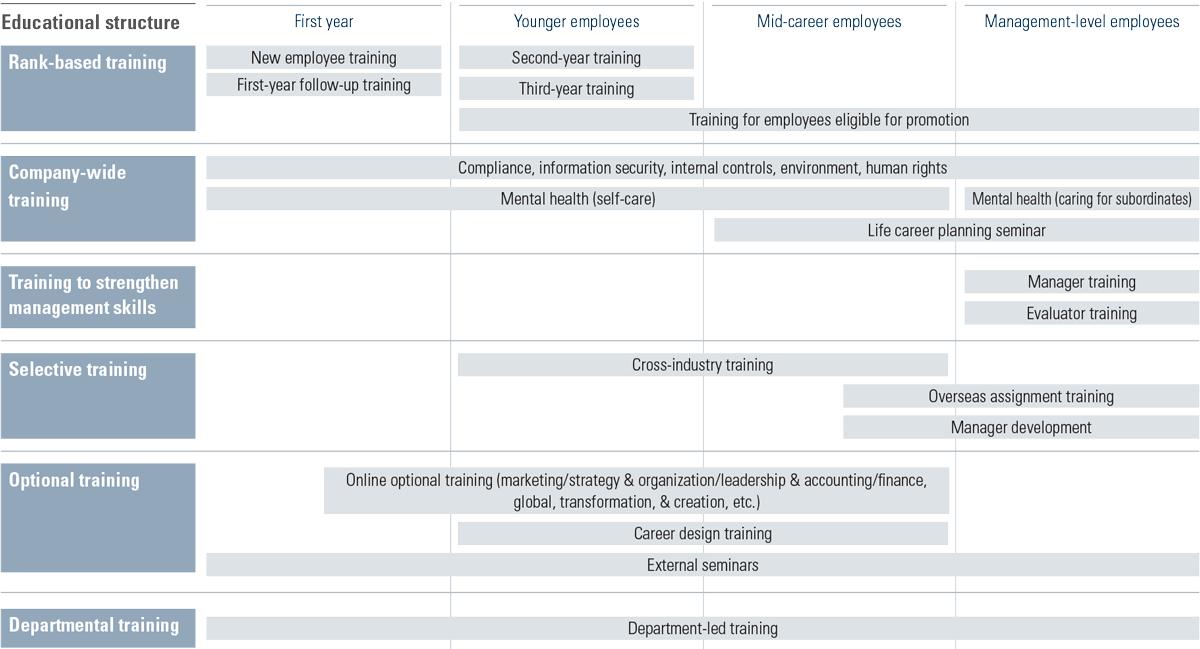

Human Resource Training Initiatives

Our Training System was restructured in fiscal 2012 to support the growth of each and every employee based on the type of human resources that Itoki seeks.

*Click the image to enlarge

Promotion of Human Resource Training

Itoki has established human rights policies and is actively implementing these to guarantee respect for human rights.

We have launched e-learning seminars on human rights and have focused our sights on "people" and "work" as they relate to corporate activities based on a theme of "business and human rights" in order to strengthen an understanding of what people think of human rights and what action they should take to promote them, etc.

Governance

Basic Concept

Itoki has established corporate governance to increase our corporate value based on business ethics and strict compliance with laws in order to ensure compliance and administrative transparency, and to increase trust in the company through the active disclosure of information.

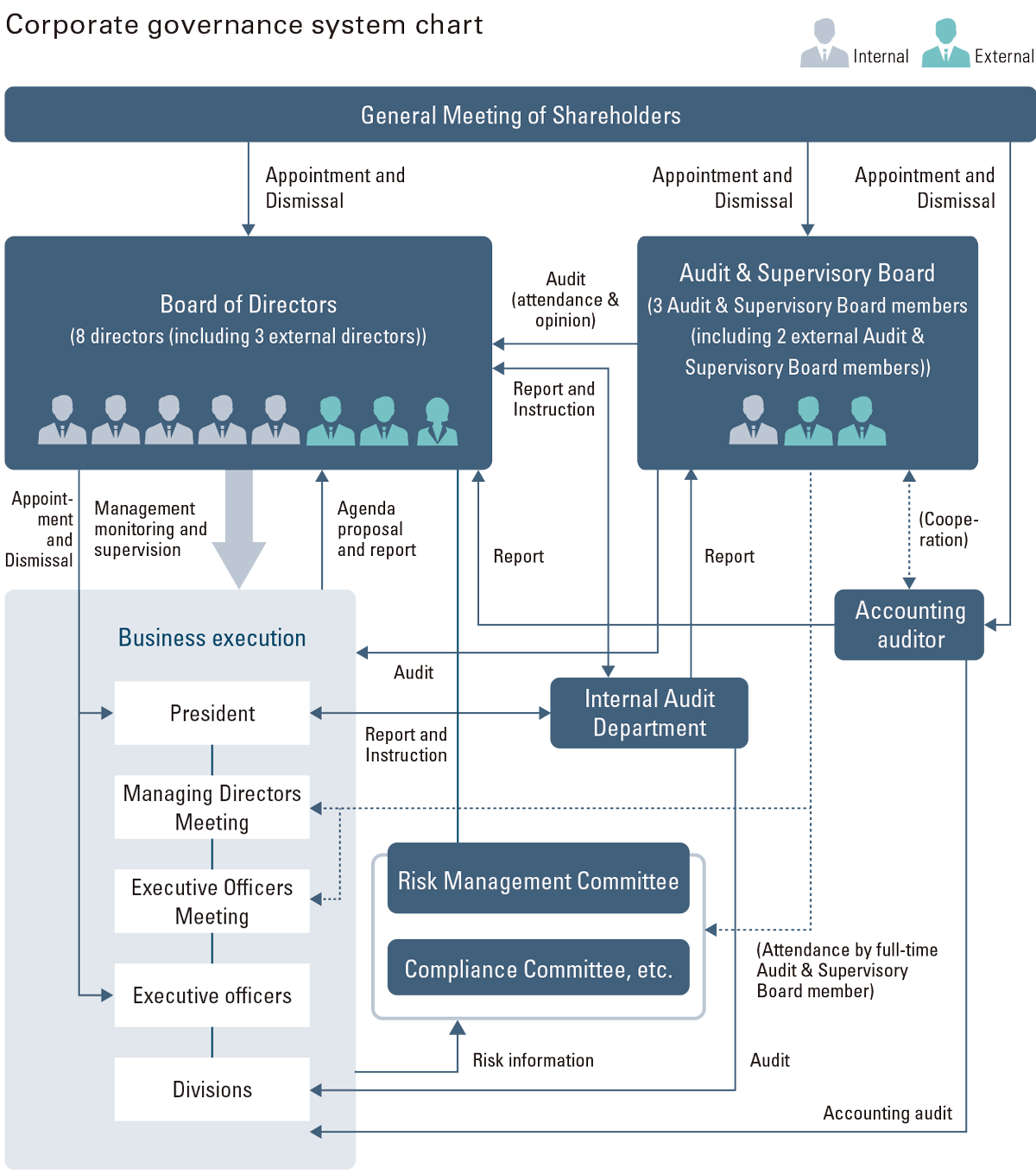

System Overview

Itoki has installed a Board of Directors consisting of eight directors, including three from outside of the company, and a Board of Auditors consisting of three auditors, including two from outside of the company. The Board of Directors oversee important administrative decision-making and the execution of duties. In addition to this, we installed an Executive Officer System in 2005 to strengthen our execution of duty functions, and to improve administrative efficiency. The Board of Auditors overseas the progress made during the execution of duties by the directors. In addition, the accounting auditors also audit our accounts from the viewpoint of account processing legality and the appropriate disclosure of information to investors. We have also established an internal auditing division independent of the executive division to ensure that internal auditing is carried out thoroughly for the entire Group.

*Click the image to enlarge

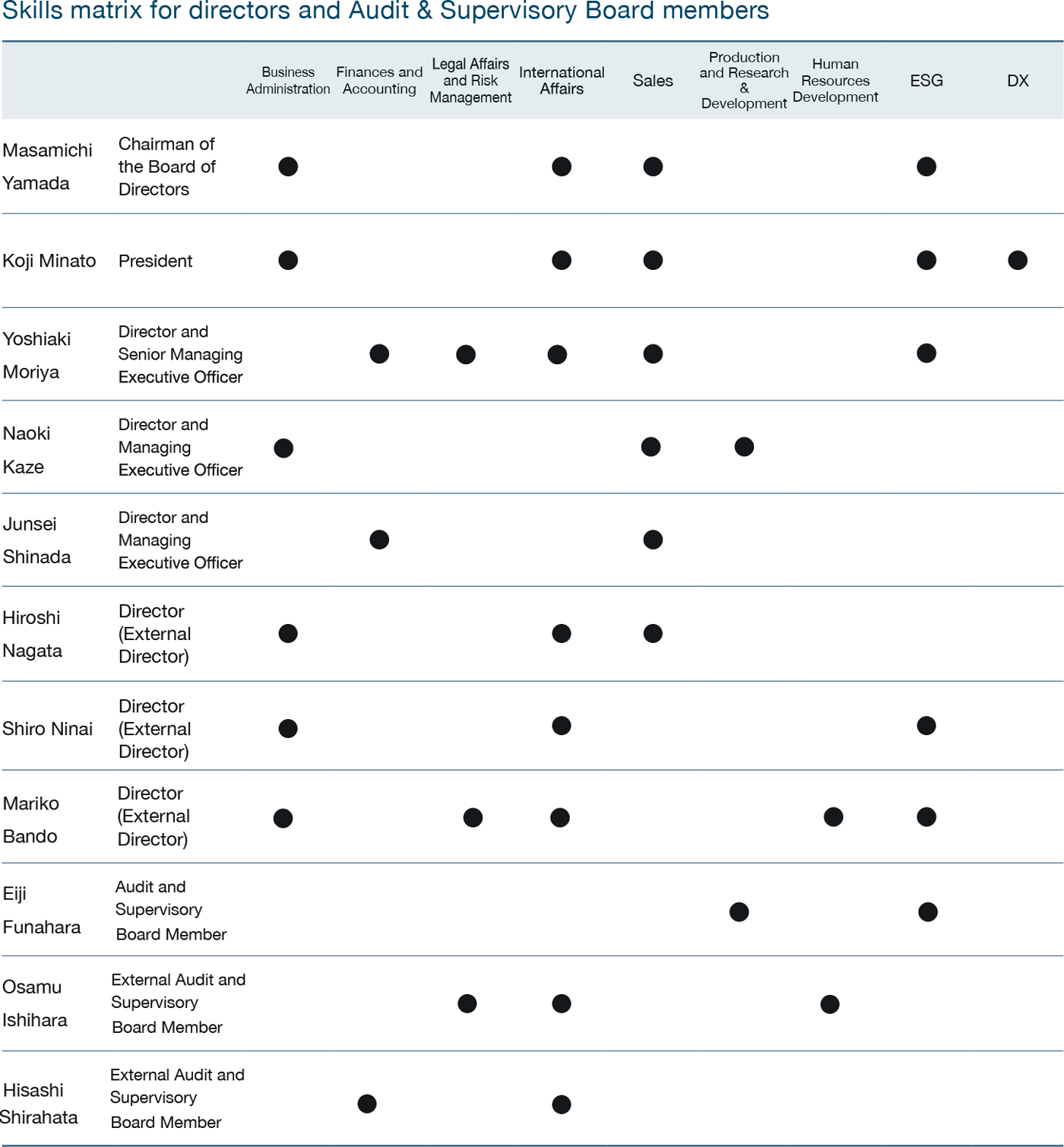

Director Diversity

The Board of Directors consists of a well-balanced group of diverse directors with the high level of skills required for responsibly enacting the Itoki Group's administrative policies and appropriately supervising its business affairs.

*Click the image to enlarge